Close search

Published :

/

Published :

/ Posted by : Retch

Posted by : RetchEnvironmental controller is a kind of intelligent control equipment using the principle of induction to control the exhaust air, temperature control, drinking water and other equipment in the chicken coop, so that the chicken coop environment is always maintained in the optimal range for animals. At present, this equipment is widely used in chicken farms.

The appropriate temperature for egg laying is 18-25℃. When the temperature of the chicken coop reaches 28℃ or more, the chickens become unbearably hot and show that they open their mouths to breathe and the number of breaths increases significantly.

As the temperature rises, the heat dissipation ability of chickens decreases. To ensure the normal performance of egg laying and the stability of production, we use methods such as longitudinal negative pressure ventilation to increase the wind speed of the coop and water evaporation system (wet curtain and spray) to reduce the temperature of the coop and ensure the normal growth and performance of chickens.

1. Airtight, well insulated closed longitudinal ventilation chicken coop (close all air inlets, start a 48-inch exhaust fan, the static pressure difference value in the coop, i.e., the difference in atmospheric pressure inside and outside the coop must exceed 0.12 inches of water column).

2.Safe and stable operation of the microcomputer environment controller (capable of automatic control of the exhaust system, air intake system, cooling system, roller shutter system, etc.)

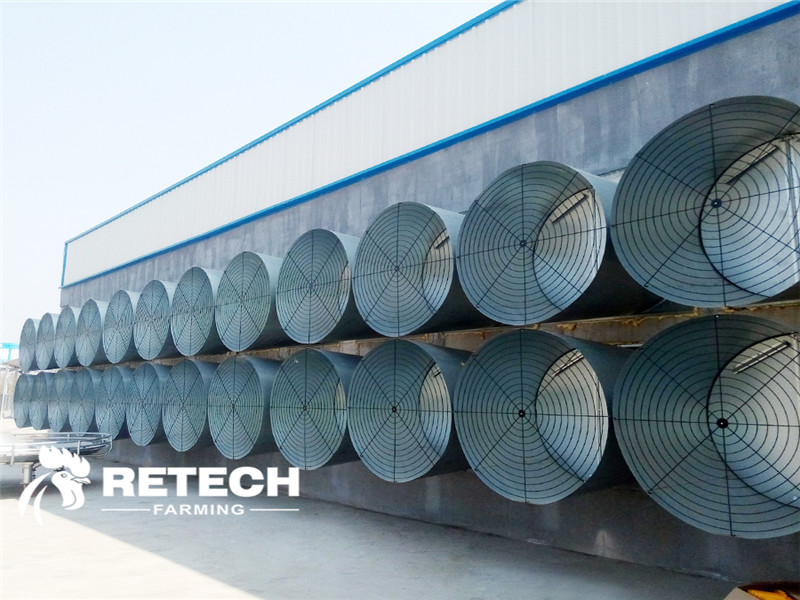

3.Sperformance of the exhaust system (mainly the exhaust fan, 48-inch exhaust fan exhaust volume of 38,000 cubic meters / hour or more).

4.Scientific air intake system (mainly ventilation small windows, 1 every 3 meters on the side wall of the chicken coop, and motors for automatic control of small window switches, etc.)

5.Good cooling system (mainly wet curtain, requiring a thickness of 15 cm or more, with a pump that automatically controls the opening of the wet curtain, etc.)

6.Roller shutter system (mainly the wet curtain into the air area control roller shutter and motor system)

7.Other equipment including negative pressure controller, temperature sensor, pulse water meter, alarm and other ancillary facilities.

It can realize the automatic control of chicken coop temperature, ventilation system, cooling system and the accurate measurement of chicken coop feeding system and drinking water system as well as the intelligent control of lighting system.

Provide enough fresh air (oxygen) for the environment in the chicken coop, exclude exhaust gases and toxic gases (ammonia, carbon dioxide), ensure the best humidity and suitable temperature in the chicken coop, meet the needs of chicken growth, and maximize the production potential of chickens.

Environmental control system mainly uses the wind cooling effect produced by wind speed and the direct cooling effect produced by wet curtain to achieve the reduction of chicken body temperature and air replacement.

In the exhaust part, the ventilation level of the chicken coop is set according to the temperature of the coop, and each ventilation level controls the number of fans running accordingly.

In the air intake section, the controller closes the small window and starts the longitudinal ventilation system completely, setting the maximum and minimum static pressure difference values of the chicken coop environment controller according to the outside temperature of the chicken coop. As the actual outside temperature changes, the actual static pressure difference value of the chicken coop changes, and the controller controls the wet curtain through the connected curtain motor.

The controller controls the size of the air inlet area of the wet curtain through the connected curtain motor to realize the actual static pressure difference value of the chicken coop and the target static pressure difference value are equal to ensure that the chicken coop reaches a certain wind speed.

When the temperature of the chicken coop reaches 30℃, the environmental controller can start the wet curtain water pump to cool down the wet curtain and achieve the purpose of reducing the air temperature in the chicken coop.