Close search

Published :

/

Published :

/ Posted by : Retch

Posted by : RetchChicken farm ventilation and cooling management is very important, chicken farm chicken coop chicken body temperature, fast breathing, metabolism, respiration requires oxygen and carbon dioxide emissions is the same weight of other animals 2 to 3 times.

In summer, the prerequisite for effective ventilation of chicken coops is that the airtightness must be maintained so that fresh air enters the coop from the required place (at the side wall vent or wet curtain).

Therefore, the farm is required to check the airtightness of each coop, especially at the doorway in the middle of the coop, at the manure barrier and at the connection between the wet curtain and the coop. Longitudinal ventilation must ensure that air should enter the coop from both sides of one end of the coop, not from only one side. Air entering the coop from both sides can fully mix the air in the coop and will not produce ventilation dead ends.

Only the formation of a certain negative pressure in the chicken coop to ensure that the ventilation into the coop has a certain wind speed, horizontal ventilation requires a wind speed of 3 m ~ 5 m per second, vertical ventilation at the wet curtain, over the curtain wind speed of 1.5 m ~ 2 m per second, the wind speed of the chicken back requires 2 m ~ 3 m per second.

The maximum wind speed at the back of the chickens should not exceed 3 meters per second, more than 3 meters, the chickens are prone to adverse symptoms. The negative pressure in the chicken coop is generally 0.05 to 0.08 appropriate, and cannot exceed 0.1 inches of water column.

The field should observe and record the negative pressure of the chicken coop to prevent excessive negative pressure in the coop. The air inlet pipe connected to the negative pressure controller should not be placed in the middle of the coop in the work room, but must be placed outside and connected to the atmospheric pressure.

If the temperature difference between day and night is too large or the weather is unpredictable, you need to use mixed ventilation to ensure the temperature of the chicken coop. So when transitioning from horizontal to vertical venting, you must pay attention to the management of the air inlet.

When the fan is switched from primary to secondary or tertiary start, the corresponding air inlet must be adjusted to reduce the negative pressure in the chicken coop, so that the front and rear of the coop have uniform wind speed and consistent temperature. For example, gradually open the area of the wet curtain and increase the area of the vent, otherwise the negative pressure in the chicken coop will be too large, affecting the efficiency of fan use.

The air flow above the chickens can produce a convection cooling effect, thus removing the moisture released by the chickens' normal breathing and panting. The flow rate of air throughout the coop can produce a "wind cooling effect" on the chickens.

Whether the ventilation management of the chicken coop is effective and the chickens are comfortable, we cannot only look at the temperature displayed by the thermometer and thermostat, but must pay attention to the body temperature of the chickens.

It is recommended to keep the temperature of the chicken coop at 22℃~24℃, and all the fans in the coop can start when the temperature reaches above 32℃, so the micro-difference between fans at all levels must be set reasonably to avoid frequent fan start. The temperature probe is placed at 20 cm from the back of the chickens in the upper cage of the chicken coop. Clean the probe with a dry rag every week to remove the dust on it and ensure the strength is sensitive.

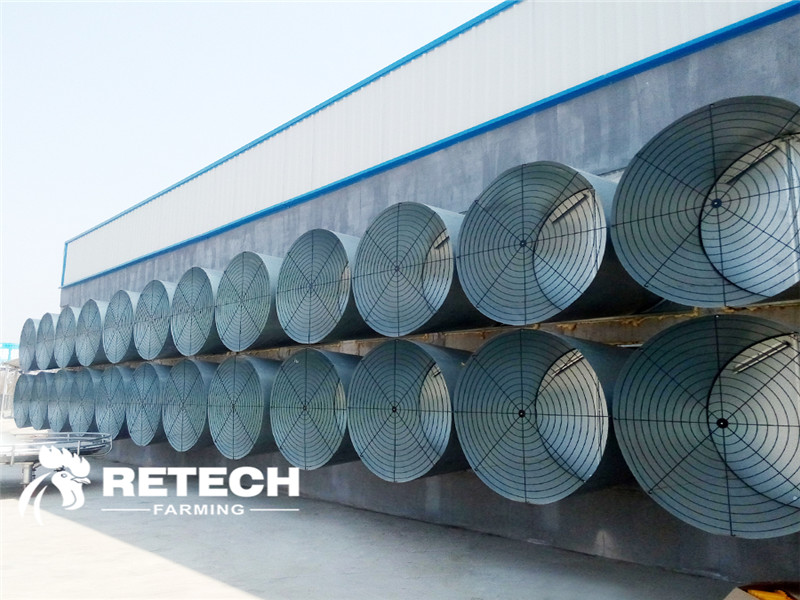

Ventilation and cooling equipment maintenance. Regularly carry out reasonable maintenance and repair of the ventilation and cooling equipment in the chicken coop to ensure the best performance.