Close search

Published :

/

Published :

/ Posted by : Retch

Posted by : RetchThe successful research of nipple drinkers in modern breeding equipment production has effectively solved the problem of cross-infection caused by water troughs for large-scale chicken breeding, and also solved the problem of reducing the amount of water and sewage discharge, reducing the spread of germs, and playing a vital role in keeping chicken manure dry and maintaining a good air quality environment in the chicken house.

The automatic drinking system composed of nipple waterer and its accessories is suitable for both flat and cage breeding, and the height of the cage can reach 8 layers, and can meet the drinking needs of chickens from chicks to adults at different ages.

Automatic feeding system generally consists of control device, drive device, feeding device, lifting suspension system device. The height of the feeding tray can be raised and lowered according to the feeding volume of poultry of different ages and breeds, which can meet the whole process of feeding poultry from 1 day old to finished products.

The feed delivery system runs smoothly and can quickly deliver feed to each tray and ensure sufficient feed. It not only reduces the labor cost of manual feeding, but also avoids cross-infection and transmission of mobile viruses caused by manual feeding. In addition, automatic feeding system, automatic manure cleaning equipment, automatic egg collection equipment, egg boxes, etc. are also widely used in various large-scale farms.

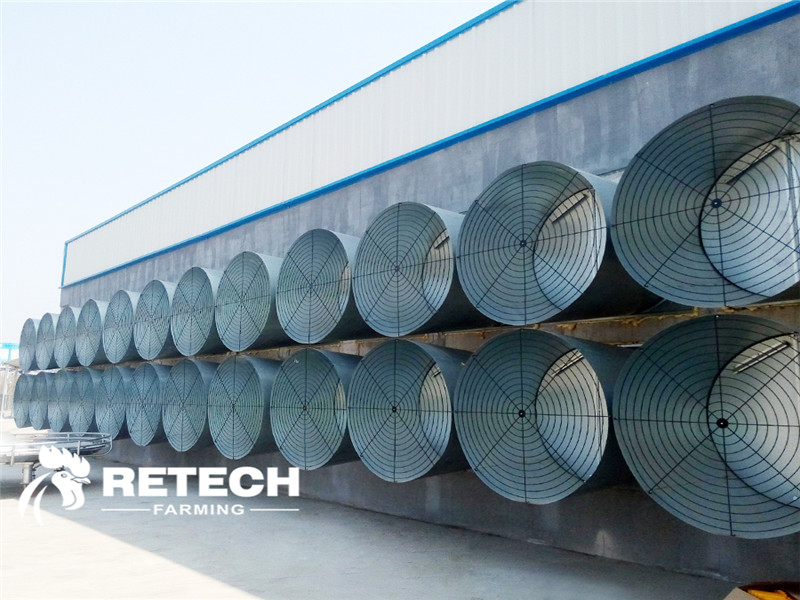

In the environmental control technology, we have developed wet curtain cooling technology and large fans and longitudinal ventilation equipment. Wet curtain cooling system economically and effectively solves the technical problems of large-scale chicken breeding in the hot summer areas of China.

Wet curtain cooling and longitudinal ventilation airflow organization mode, generally solve the problem of high temperature in summer to reduce production and increase the rate of dead poultries, which is an important breakthrough in the modern breeding environment control technology. The application of low-pressure high-flow fan not only guarantees the effective supply of fresh air needed for high-density breeding, but also saves 20%-30% of energy consumption for ventilation in chicken coops.

Retech has been exploring and studying the poultry industry for over 30 years, we’re very familiar with your local market, helped many chicken farmers to achieve great success by renovating their farms and upgrading their equipment, with more than 30 years of production experience, we can design and manufacture both chicken house and chicken cage based on your need and requirement, we can provide clients with automatic layer cage, broiler cage, and pullet cage, with best quality raw material, state of art of technology, competitive price, good service before/after the sale.

Website: www.retechfarming.com

Facebook: @retechfarmingchickencage 100k Followers

Whatsapp: +8618561818859

Email: info@retechfarming.com